Cooling Systems Using Sea Water or Clear Water

Cooling systems that utilize sea water or clear (fresh) water are essential in various industries, including power generation, marine applications, and industrial processes. Valves play a critical role in controlling the flow, pressure, and direction of water in these systems. Selecting the right type of valve is crucial to ensure reliability, efficiency, and longevity, especially considering the distinct characteristics of sea water and clear water.

Applications

Valves in seawater cooling systems are commonly found in:

- Marine engine cooling circuits

- Desalination plants

- Power station condenser cooling

- Offshore platforms

In clear water cooling systems, valves are used in:

- Industrial process cooling

- HVAC systems

- Municipal water treatment plants

- Chiller and heat exchanger units

Key Selection Criteria

- Corrosion Resistance: Essential for seawater applications; less critical for clear water.

- Flow Requirements: Choose valve type based on required flow control and shutoff capabilities.

- Maintenance Needs: Consider ease of inspection, cleaning, and replacement.

- Pressure and Temperature Ratings: Ensure the valve can withstand system operating conditions.

- Cost and Availability: Factor in budgetary constraints and supply chain considerations.

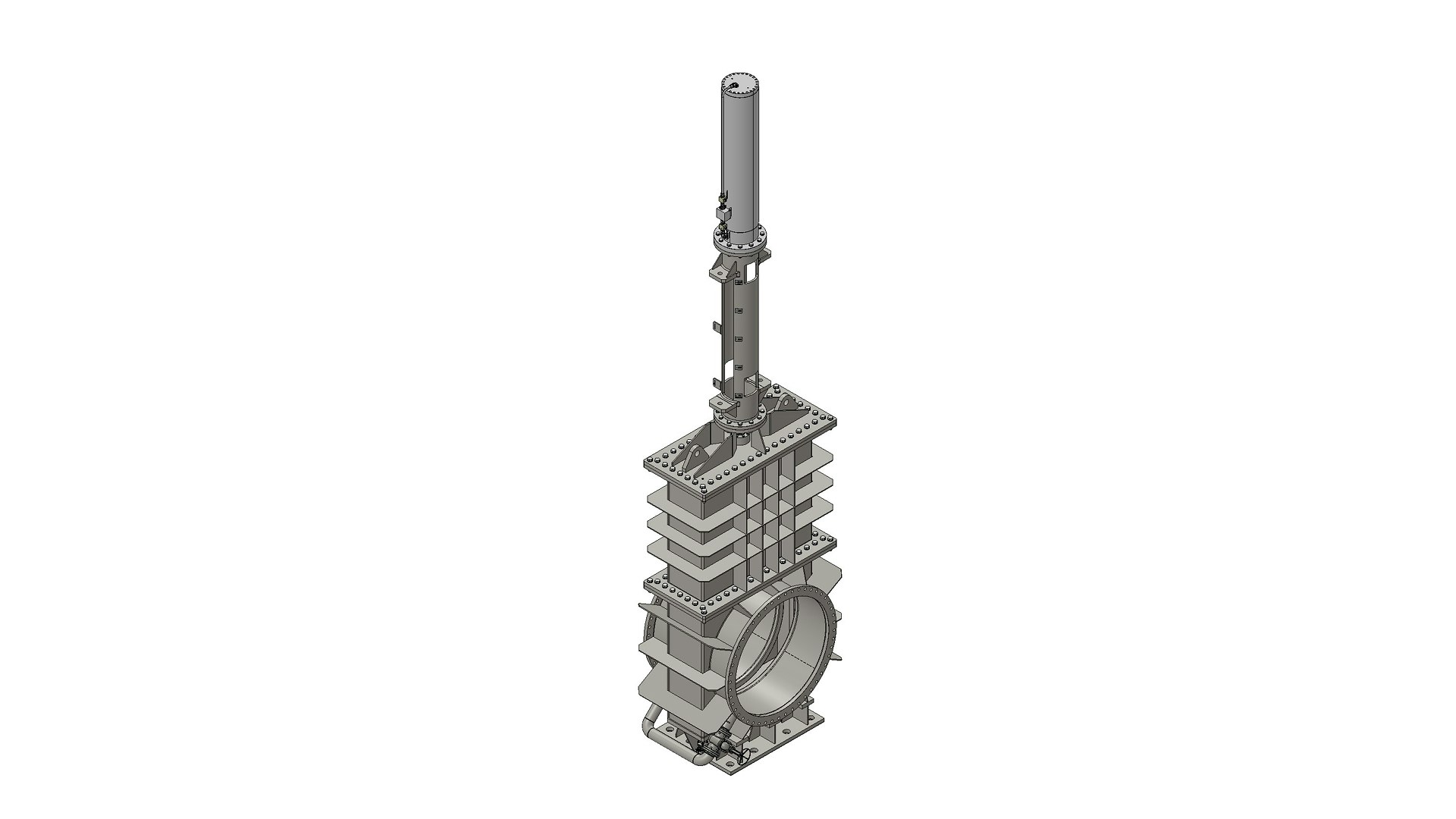

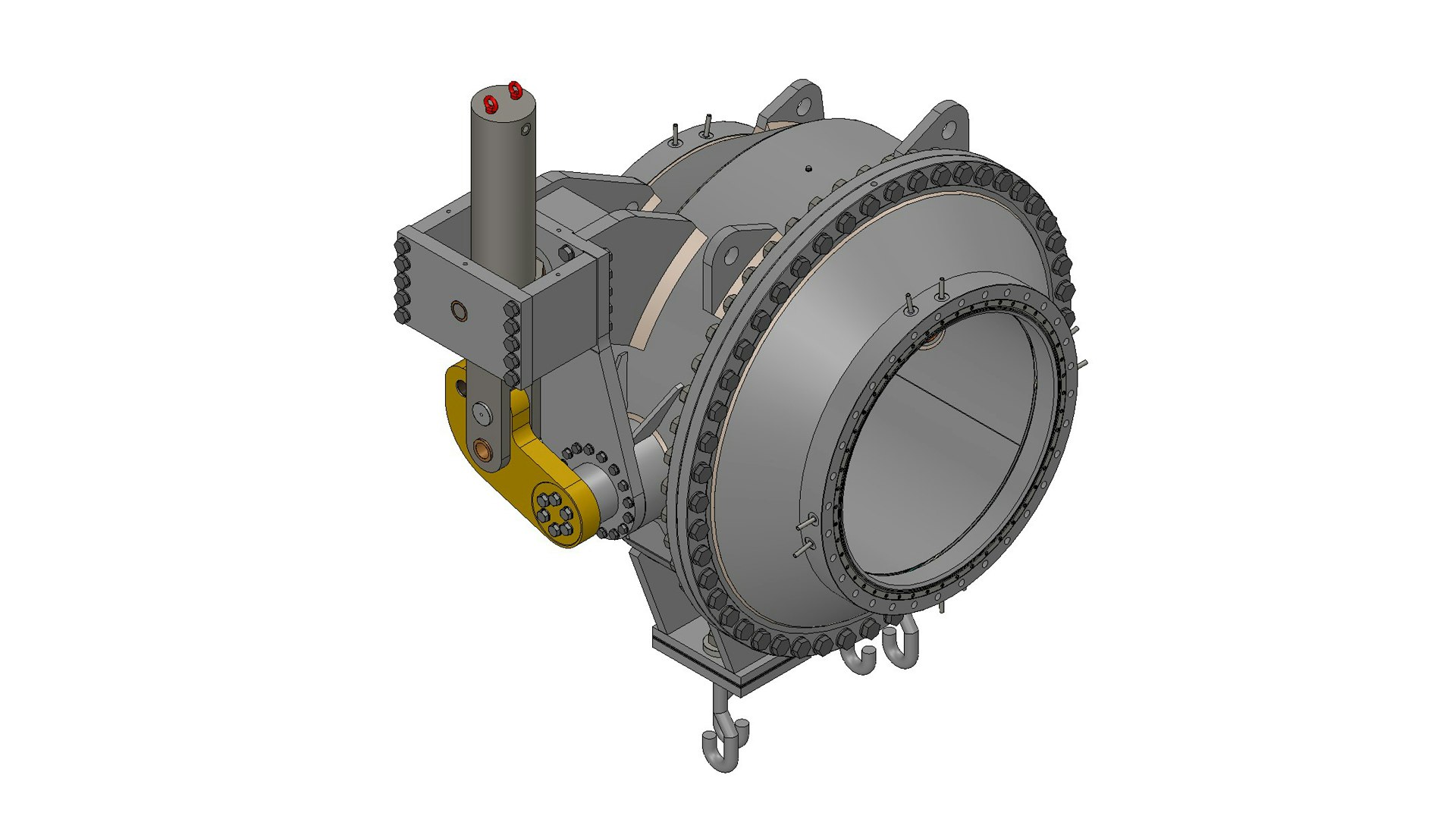

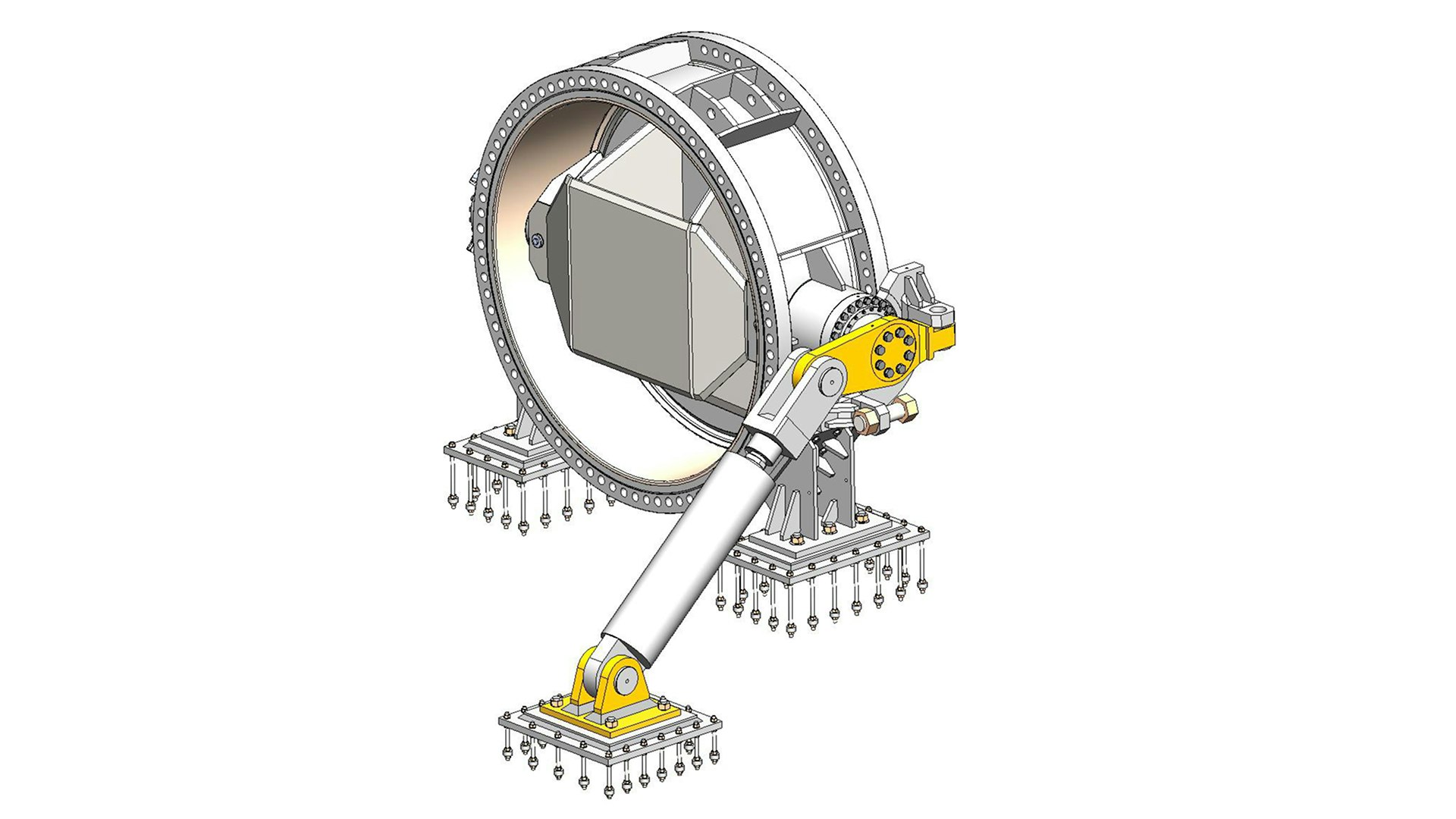

Types of Valves Used in Cooling Systems

The following are common types of valves used in cooling systems with seawater or clear water:

Material Considerations

The corrosive nature of sea water demands careful selection of valve materials. Common choices include:

- Bronze and Aluminum Bronze: Often used for sea water due to their resistance to corrosion.

- Stainless Steel: Suitable for both sea water and clear water, offering high durability and corrosion resistance.

- Duplex Stainless Steel and Special Alloys: Used in highly corrosive environments or when extended service life is required.

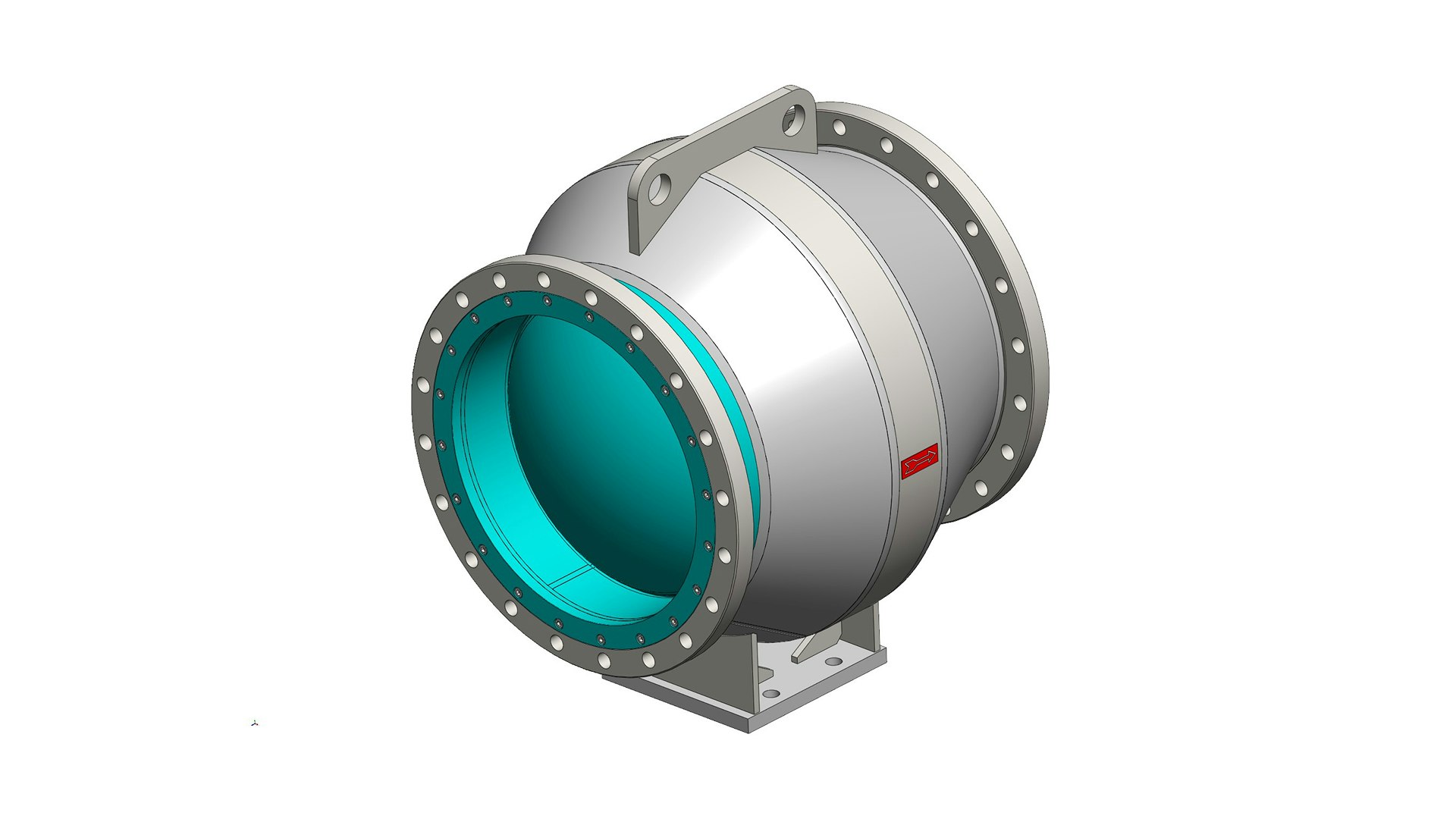

- Cast Iron or steel rubber lined an economical option for salt water cooling systems. The rubber lining protects the metal from corrosion but requires regular maintenance, as any damage can quickly lead to deterioration of the underlying metal.