Desalination

Main Functions of Valves in Desalination Plants

Valves are utilized at various stages of the desalination process, including:

- Flow regulation: controlling the amount of water entering and exiting different sections of the plant.

- Isolation: allowing sections of the plant to be shut off for maintenance or emergencies.

- Pressure control: maintaining optimal pressure levels for processes such as reverse osmosis.

- Chemical management: dosing and regulating the introduction of chemicals necessary for pretreatment or membrane cleaning.

Materials and Corrosion Resistance

One of the major challenges in selecting valves for desalination is ensuring resistance to corrosion from saline water. Common materials include:

- Stainless steel (type 316L): provides a good balance of chemical resistance and cost.

- Special alloys (such as duplex or super duplex): used for particularly aggressive conditions.

- Grey Iron with special lining such as epoxy, glass, or rubber to resist corrosion from saline water, to extend valve life, and to improve reliability in harsh environments.

Technological Challenges and Innovation

Desalination plants face demanding operating conditions: high pressures, presence of sand, suspended solids, and chemicals. Valves must be designed to minimize maintenance and failures, ensuring long-term reliability. In recent years, smart monitoring and automation systems have become more widespread, enabling real-time detection of wear or malfunctions, optimizing maintenance cycles, and reducing operational costs.

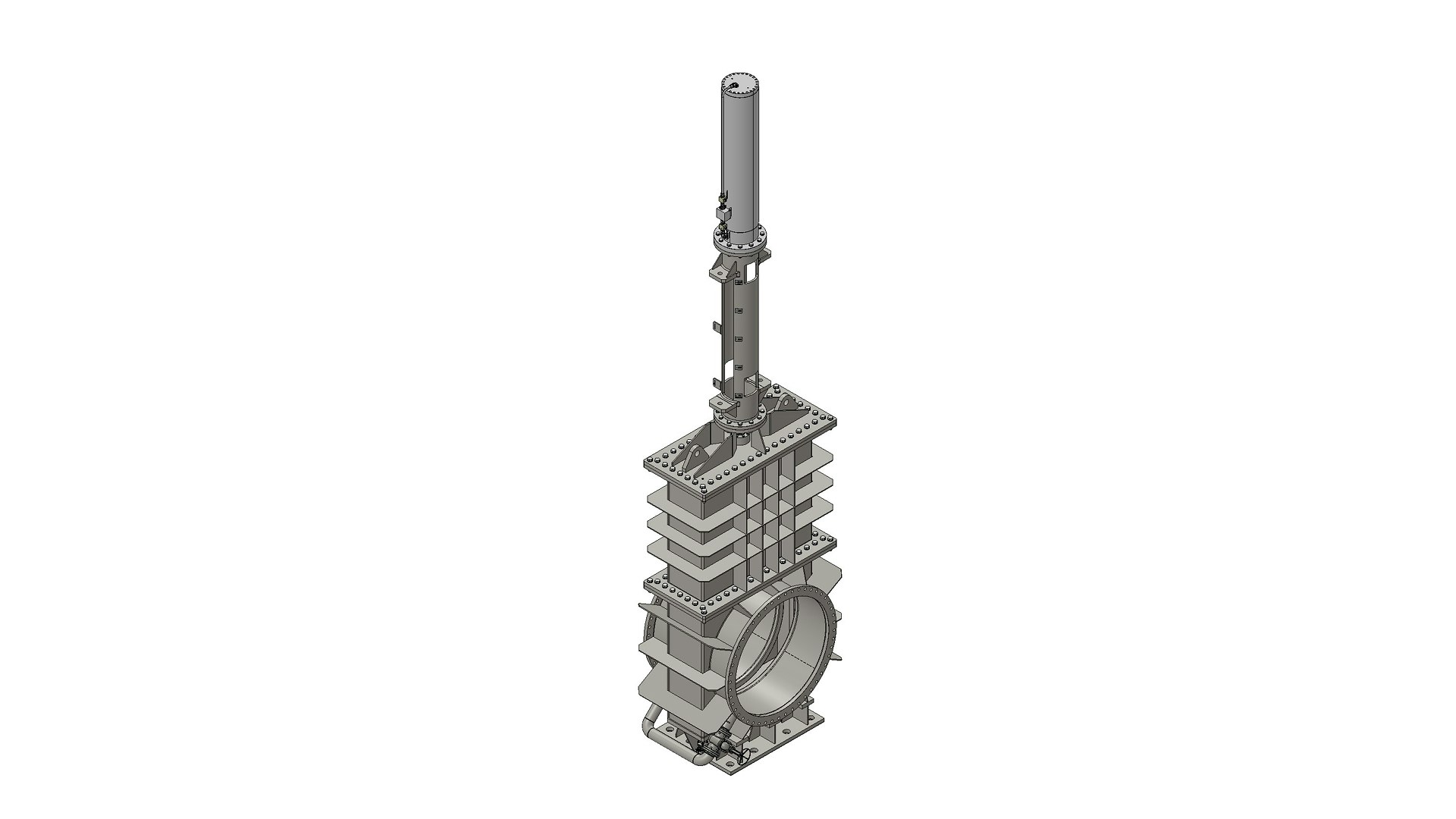

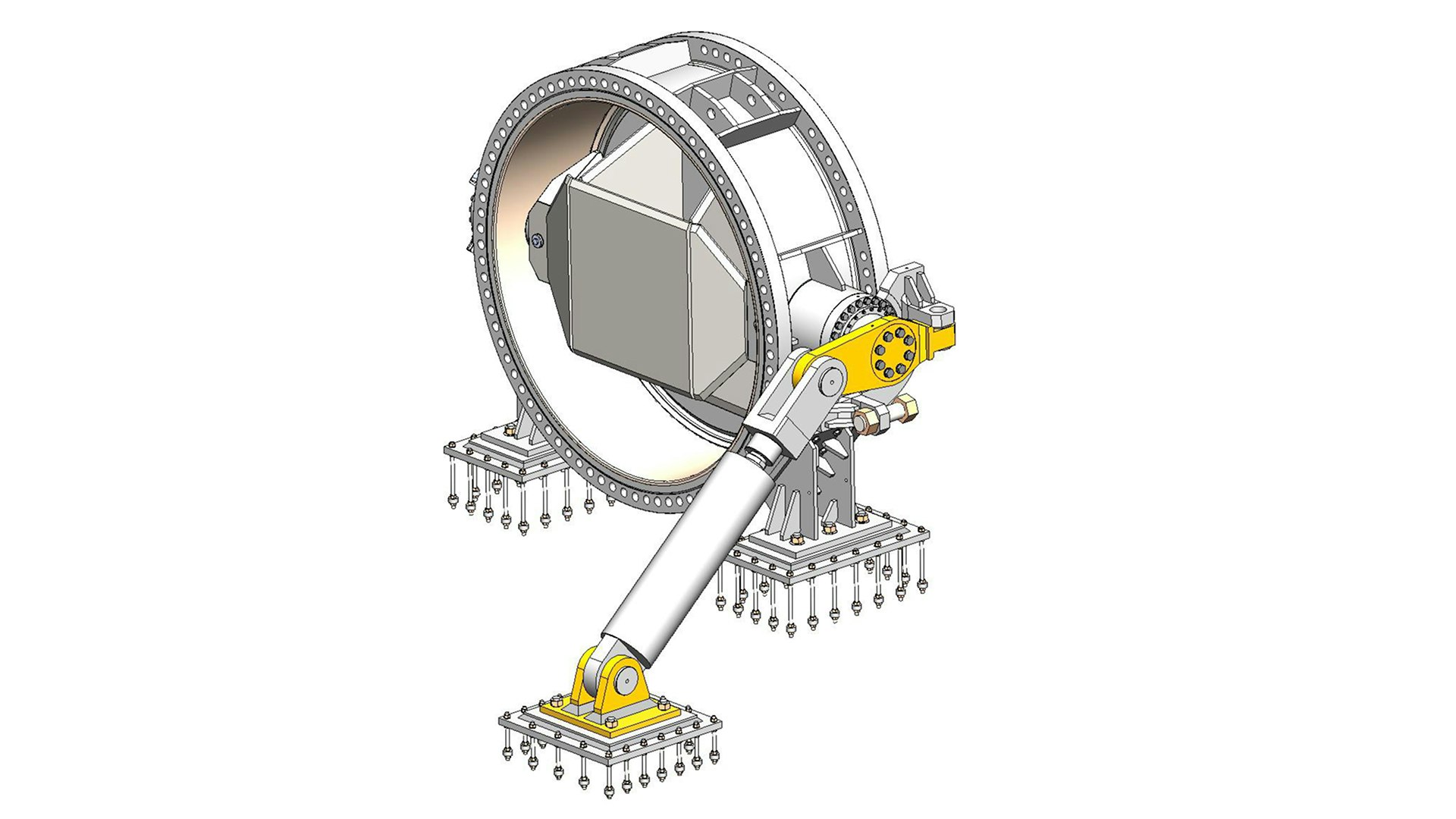

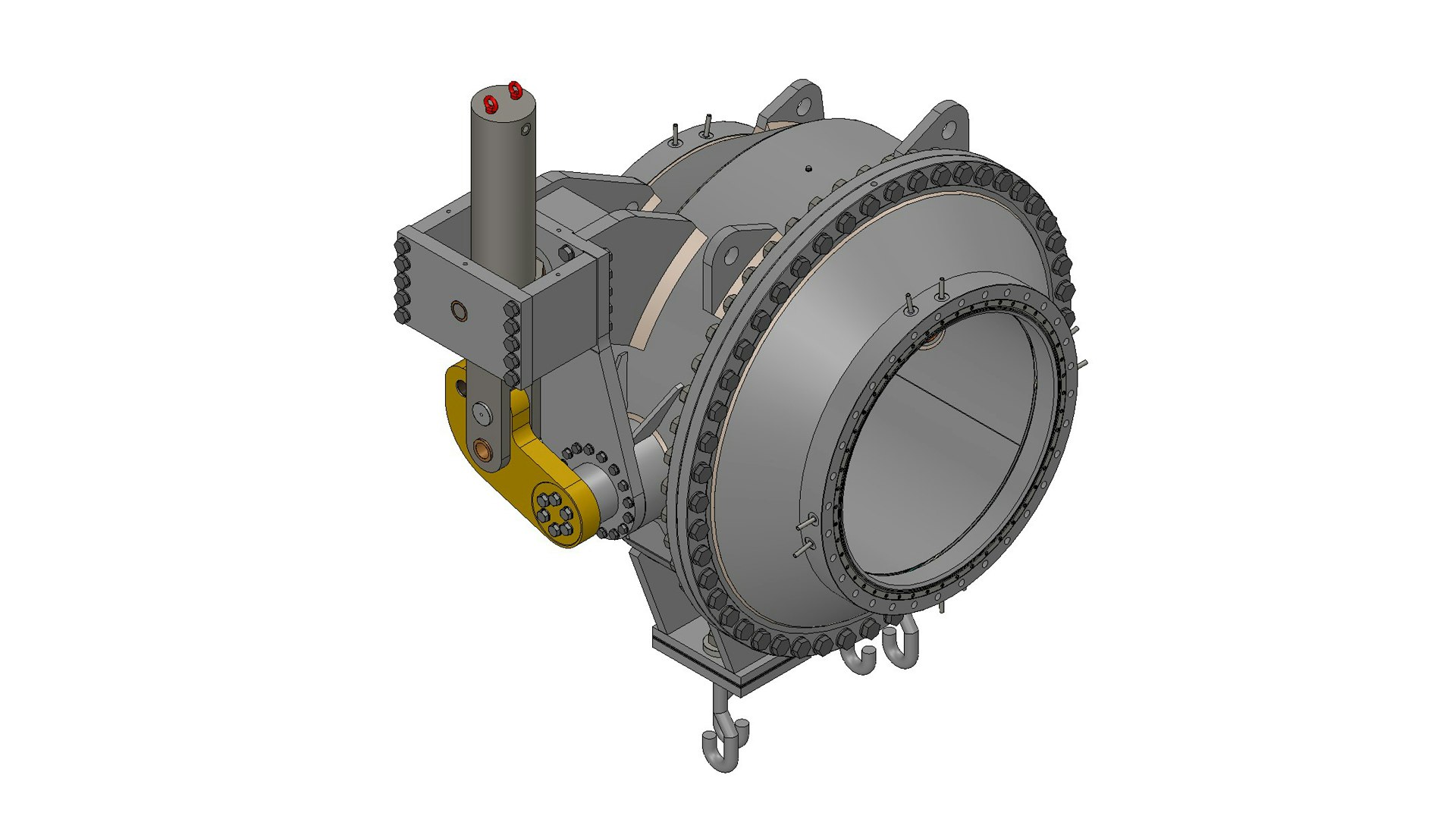

Types of Valves Used

Desalination plants employ different types of valves, such as: