Tank Storage and Reservoirs for Clear Water

Key Considerations in Valve Selection

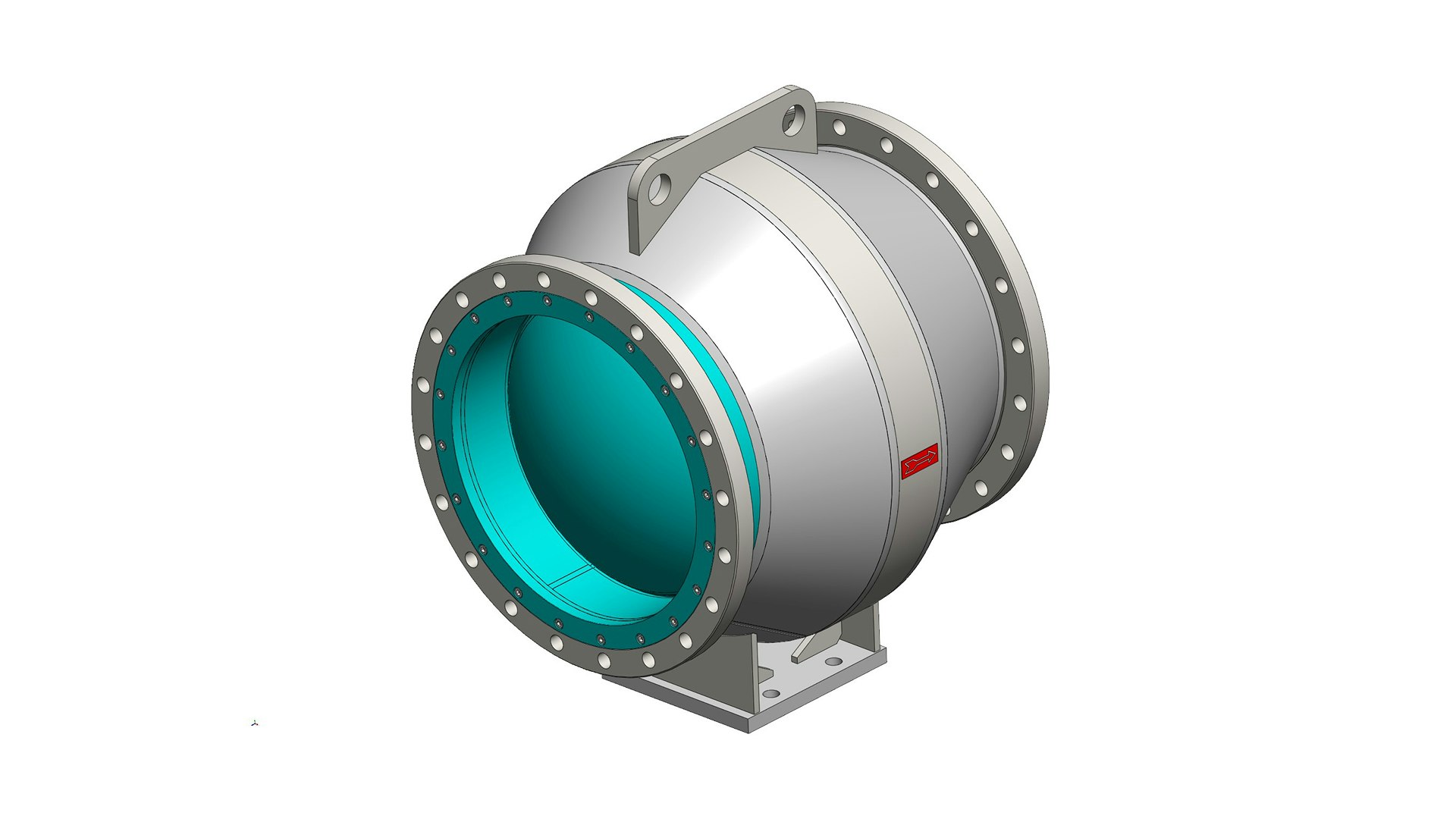

- Water Quality: For clear water, valves should be constructed from corrosion-resistant materials such as stainless steel to prevent contamination and ensure longevity.

- Operation and Maintenance: Ease of operation, accessibility for maintenance, and availability of spare parts are important factors when choosing valves for tank storage and reservoirs.

- Pressure and Flow Requirements: The valve must match the system’s pressure and flow characteristics to avoid operational issues and ensure effective control.

- Size and Installation: Valve size should be compatible with pipe diameters and tank outlets. Installation location (above or below ground, accessibility) also influences valve choice.

- Compliance and Standards: Valves should meet local and international standards for potable water systems, such as NSF/ANSI, AWWA, or ISO certifications.

Applications in Tank Storage and Reservoirs

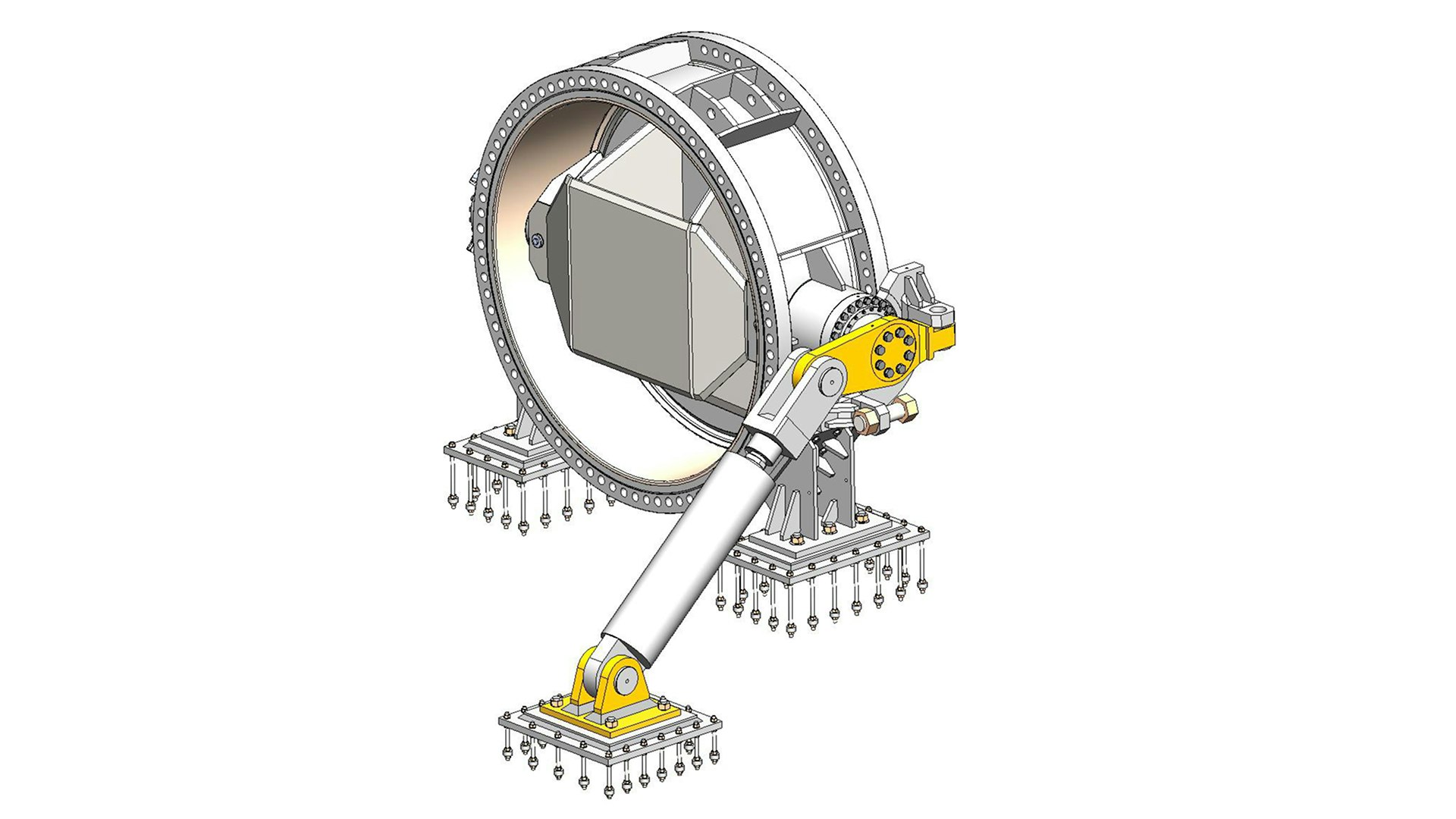

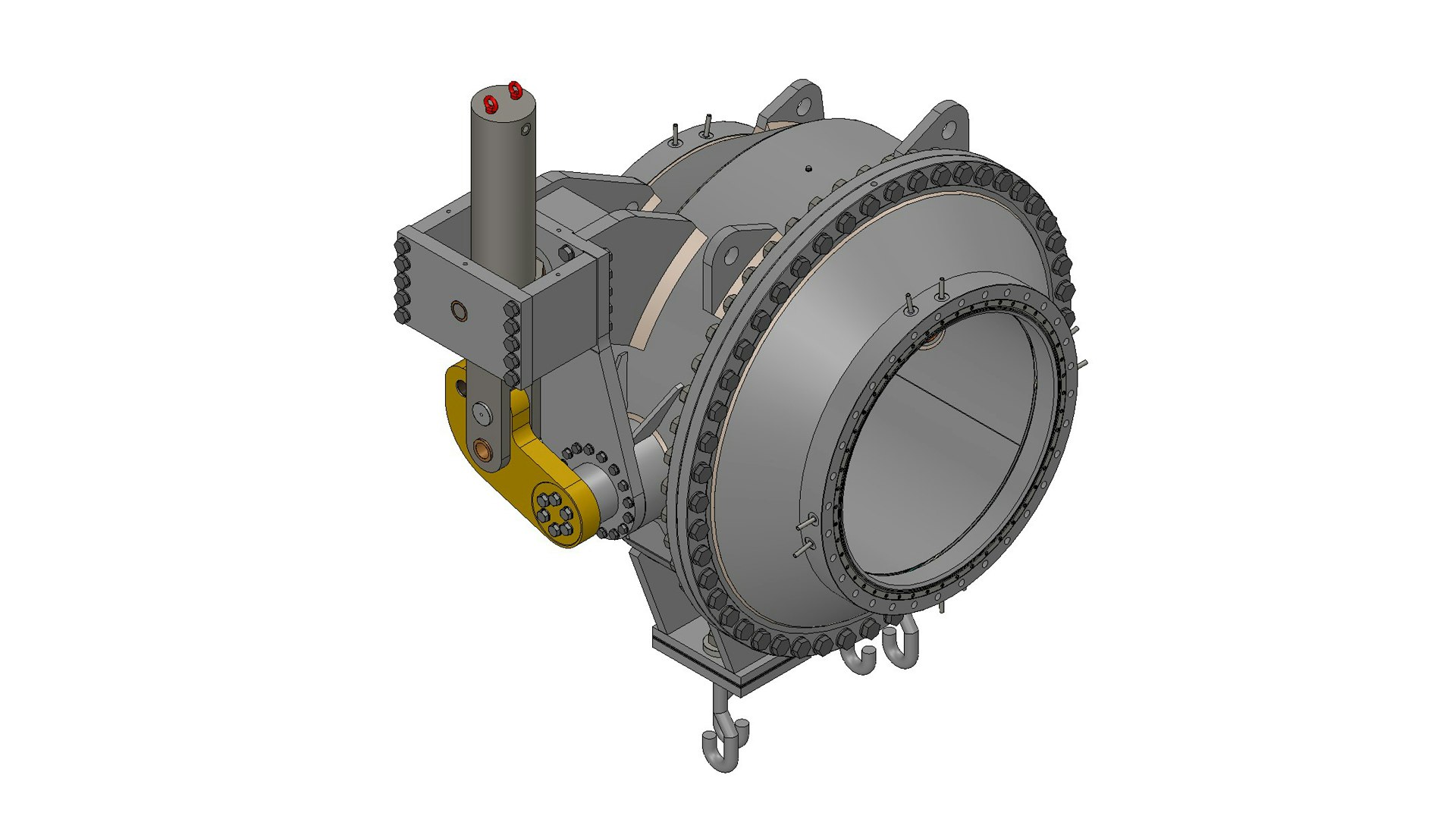

- Inlet and Outlet Control: Valves regulate the filling and emptying of tanks and reservoirs, allowing operators to control water inflow and outflow as needed.

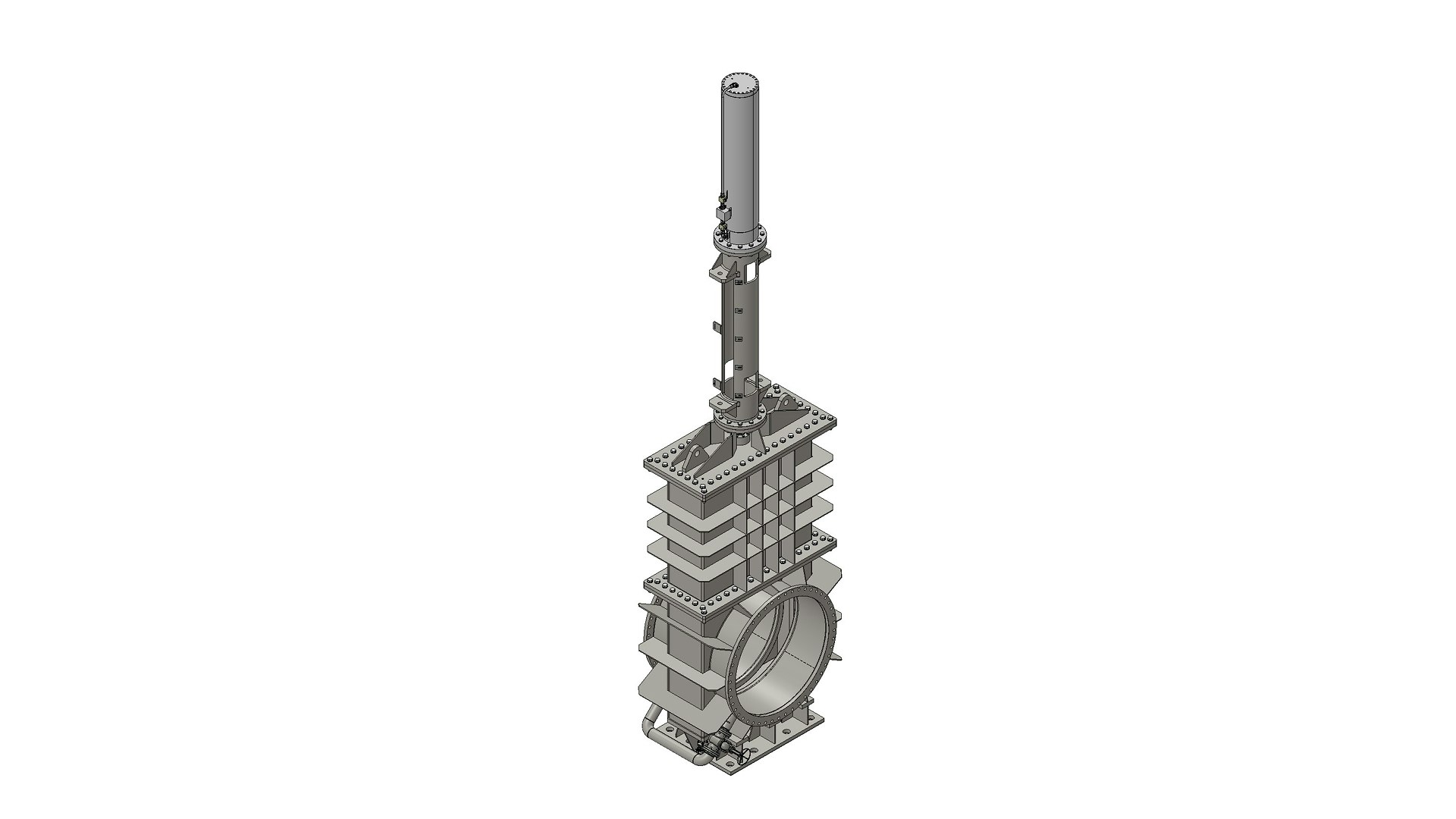

- Isolation for Maintenance: Gate or ball valves are used to isolate tanks or sections of the reservoir for cleaning, inspection, or repair without disrupting the overall water supply.

- Overflow Protection: Valves help manage overflow events by diverting excess water safely, protecting infrastructure, and preventing environmental contamination.

- Level Regulation: Automated valves, such as float or solenoid valves, can maintain desired water levels and prevent overfilling or underfilling of tanks.

- Backflow Prevention: Check valves are installed to prevent reverse flow and potential contamination of the stored clear water.